- Products

- Oncohematology

- Antibodies

- Kits

- CAR T-cell

- Euroflow

- Single reagents

- Request info

- Resources and support

- Immunology

- Antibodies

- Single reagents

- Cross match determination (FCXM)

- FcεR1

- Ig subclasses

- Single reagents

- Kits

- TiMas, assessment of tissue macrophages

- Request info

- Resources and support

- Antibodies

- Exosomes

- Accesory reagents

- Software

- Oncohematology

- Services

- Peptide Production

- Design

- Modification

- Protein Services

- Expression and purification

- Freeze drying

- Monoclonal And Polyclonal Antibody Development

- Monoclonal

- Policlonal

- Specialized antibody services

- OEM/Bulk production

- Purification

- Conjugation

- Custom Exosome Services

- Isolation and purification

- Characterization

- Peptide Production

- Shop

- Support

- About Us

- Contact

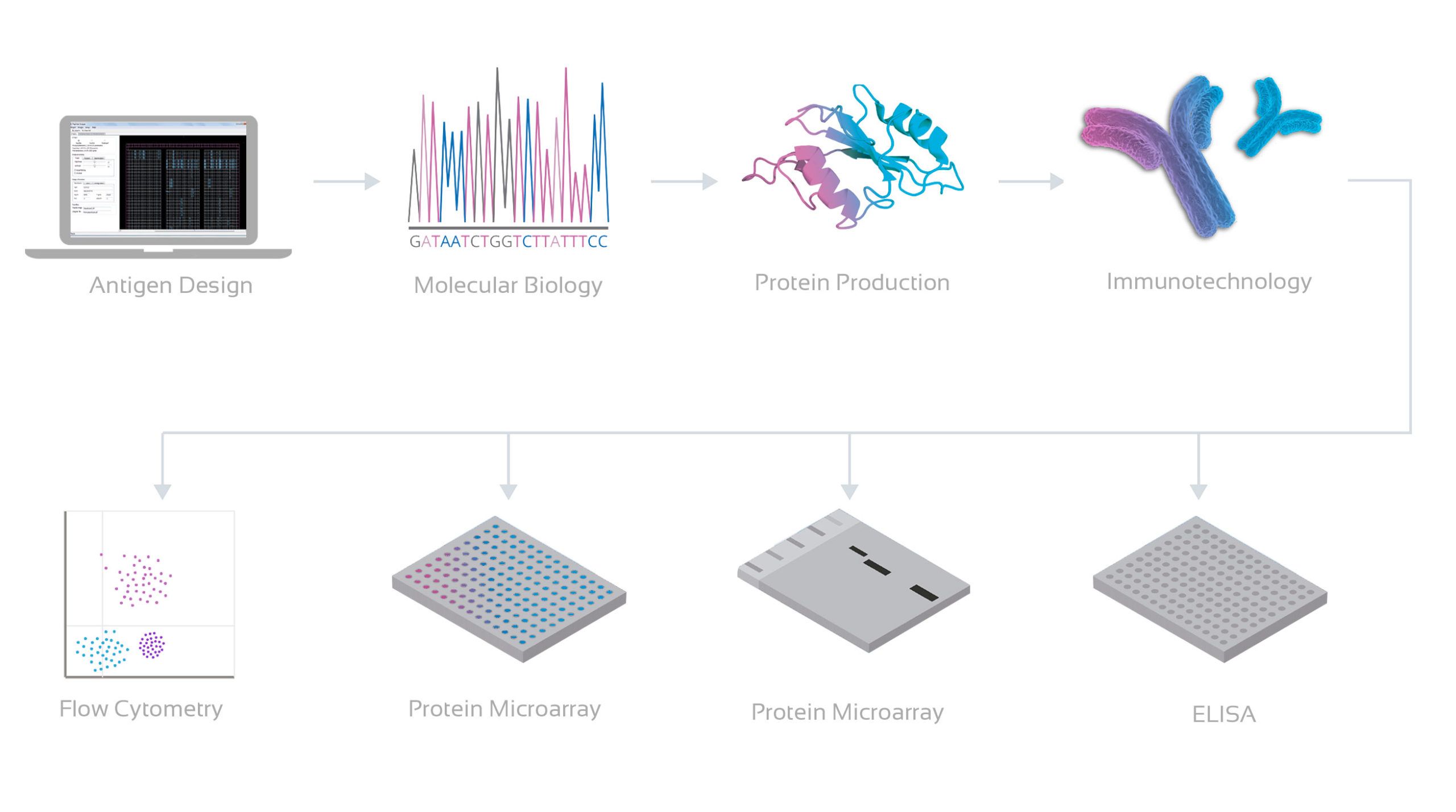

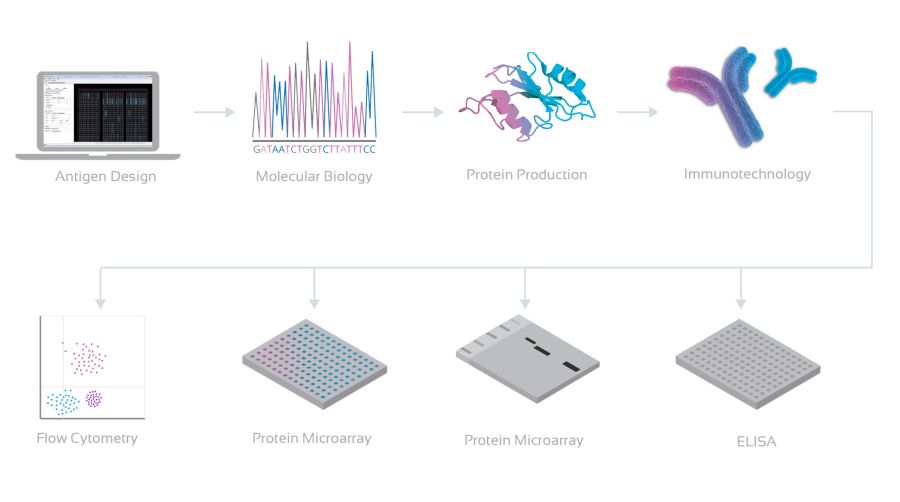

Monoclonal and Polyclonal Antibody Development

For the last few decades, the use of both monoclonal and polyclonal antibodies has become widespread in laboratories all over the world. The adaptability of these biological tools to diverse applications means that they are involved in a large number of the processes which are developed in research laboratories, and in the R&D departments of many institutions.

Custom Antibody Production

Our 15-year experience in the personalised development of antibodies for our customers has enabled us to take part in the implementation of about 150 of these processes. In turn, they have confronted us with various challenges that have led to the creation of a long list of services related to such developments. Our antibody service portfolio includes conjugation of antibodies, fragmentation, scaling production, development of immunoassays etc.

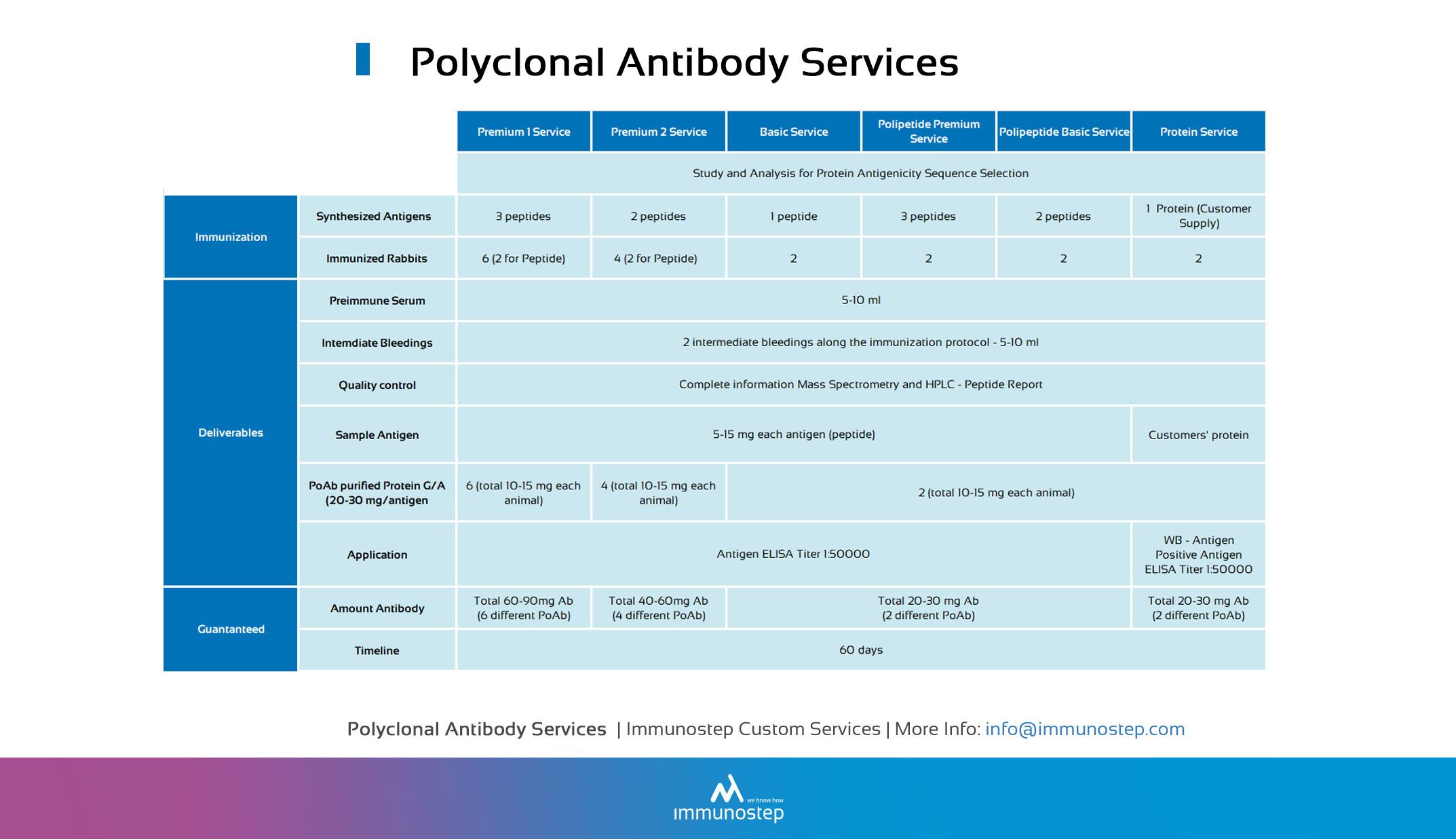

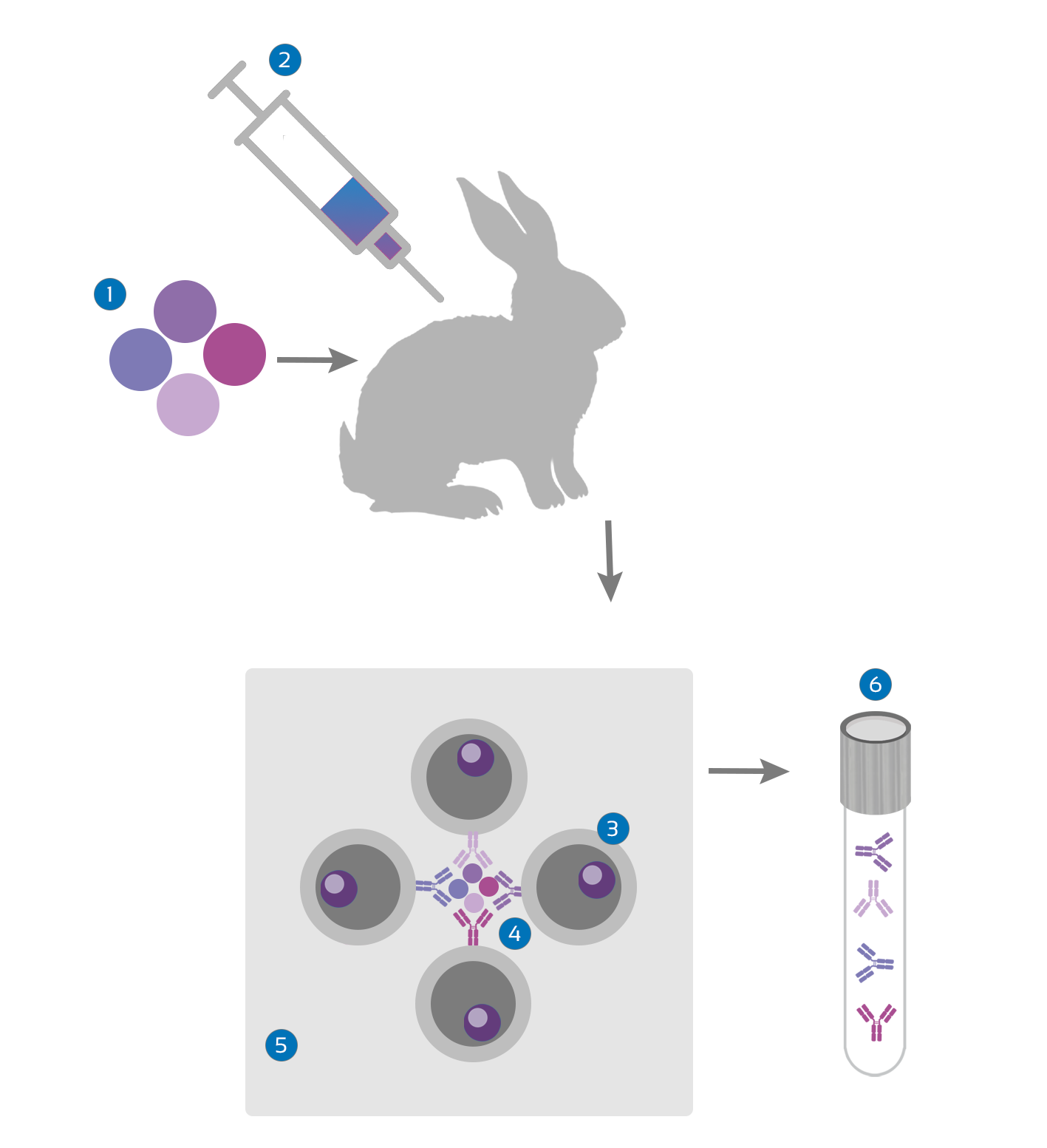

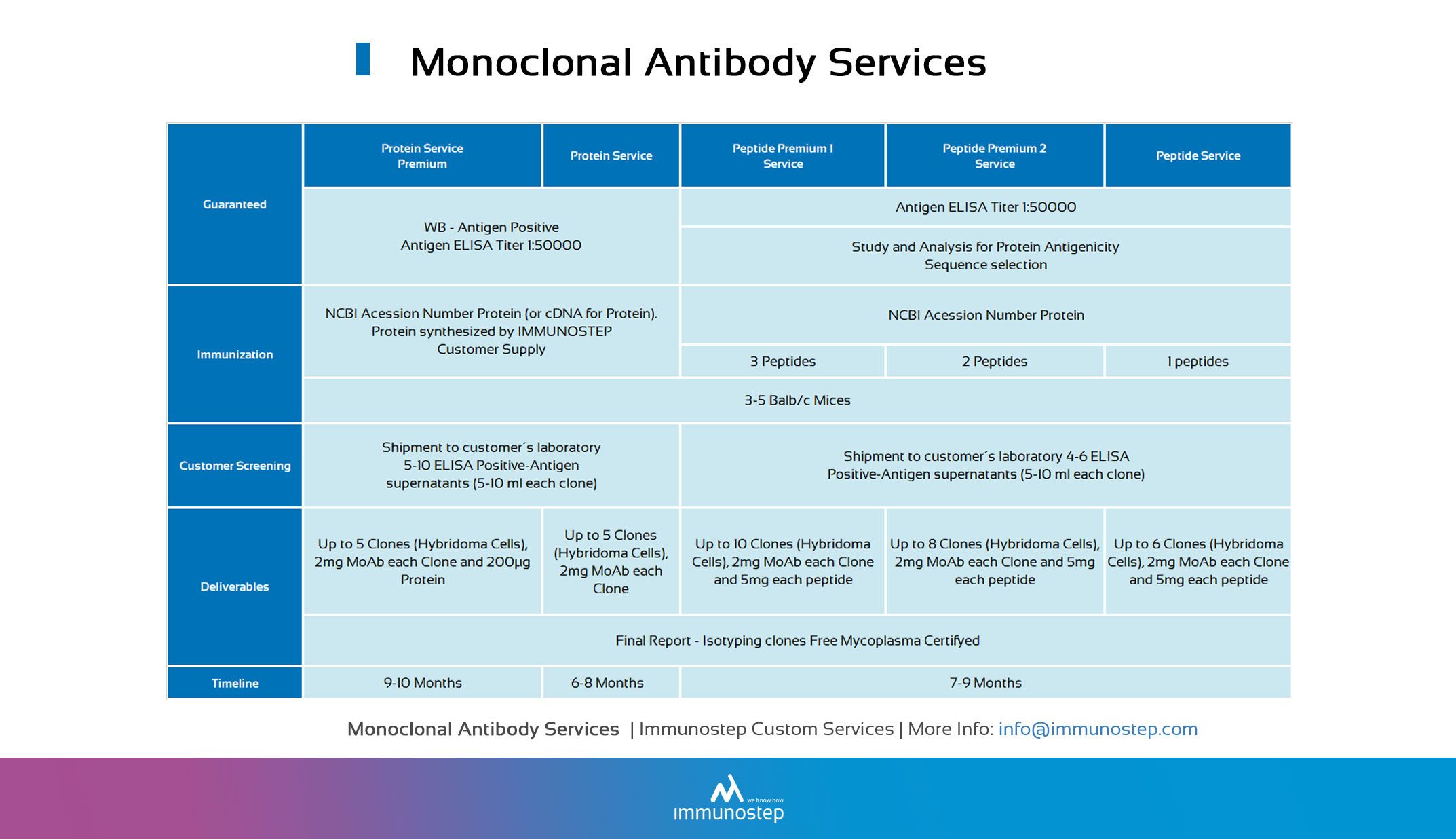

Polyclonal Antibodies

Our polyclonal antibody development service includes the production of customized polyclonal antibodies in rabbits. During the corresponding process, we will work with our clients, and we will adjust our protocols, tested in hundreds of cases, until they have been perfectly adapted to the clients’ needs. This process will not only include the design of the most suitable antigen for a given service, but also peptide synthesis, and animal immunization protocol. Following on from these steps, the purification and quality control of the antibodies will be implemented by means of an ELISA test.

Rabbit Polyclonal Antibodies

Depending on the with which the customer wishes to work, we adapt the most suitable one, ranging from straightforward target peptide sequences to the client’s cDNA, utilised as a basis, if available.

Moreover, we have standardised an immunisation protocol that has been thoroughly tested through our experience; this facilitates our knowledge of the behaviour and type of priority Igs which may interest us the most and which allow us to explore the animal’s immune system in order to adapt that response to the technical use the process has been designed for.

Apart from our team’s close relationship with the researcher, another important factor is the inclusion in our service of the purification (Protein A/G) of the antibodies from the animals serum.

This purification allows clients to achieve their goals by working with completely established material right from the start and, most importantly, it provides us with versatility in other services that can help them.

For example, specific Ag affinity purification, marked in different fluorochromes/enzymes, subsequent antibody modifications etc. These are additional services that ensure integral and completely personalised assistance.

We are looking forward to hearing about your needs.

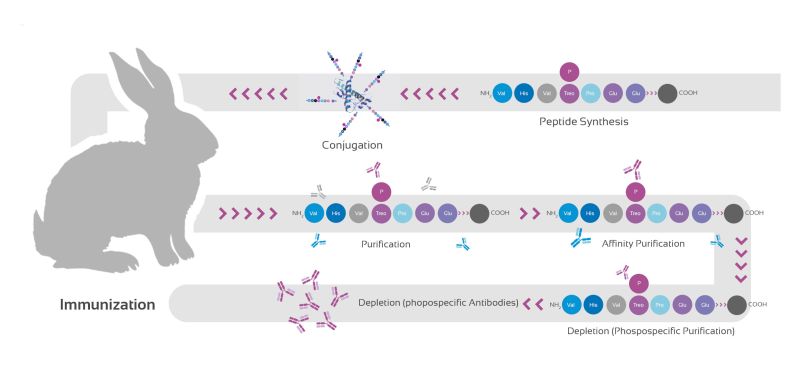

Phospho-Specific Antibodies

Working with new proteins and advances in functionality discoveries sometimes make it necessary to differentiate between the activation/functionality of markers. Post-translational modifications in proteins, especially the phosphorylation of proteins, are involved in most cell processes and this makes their study essential in the development of new strategies in regard to numerous human diseases.

Our phospho-specific antibody purification system can detect specific phosphorylations in proteins from complex high sensitivity and high specificity cell mixtures.

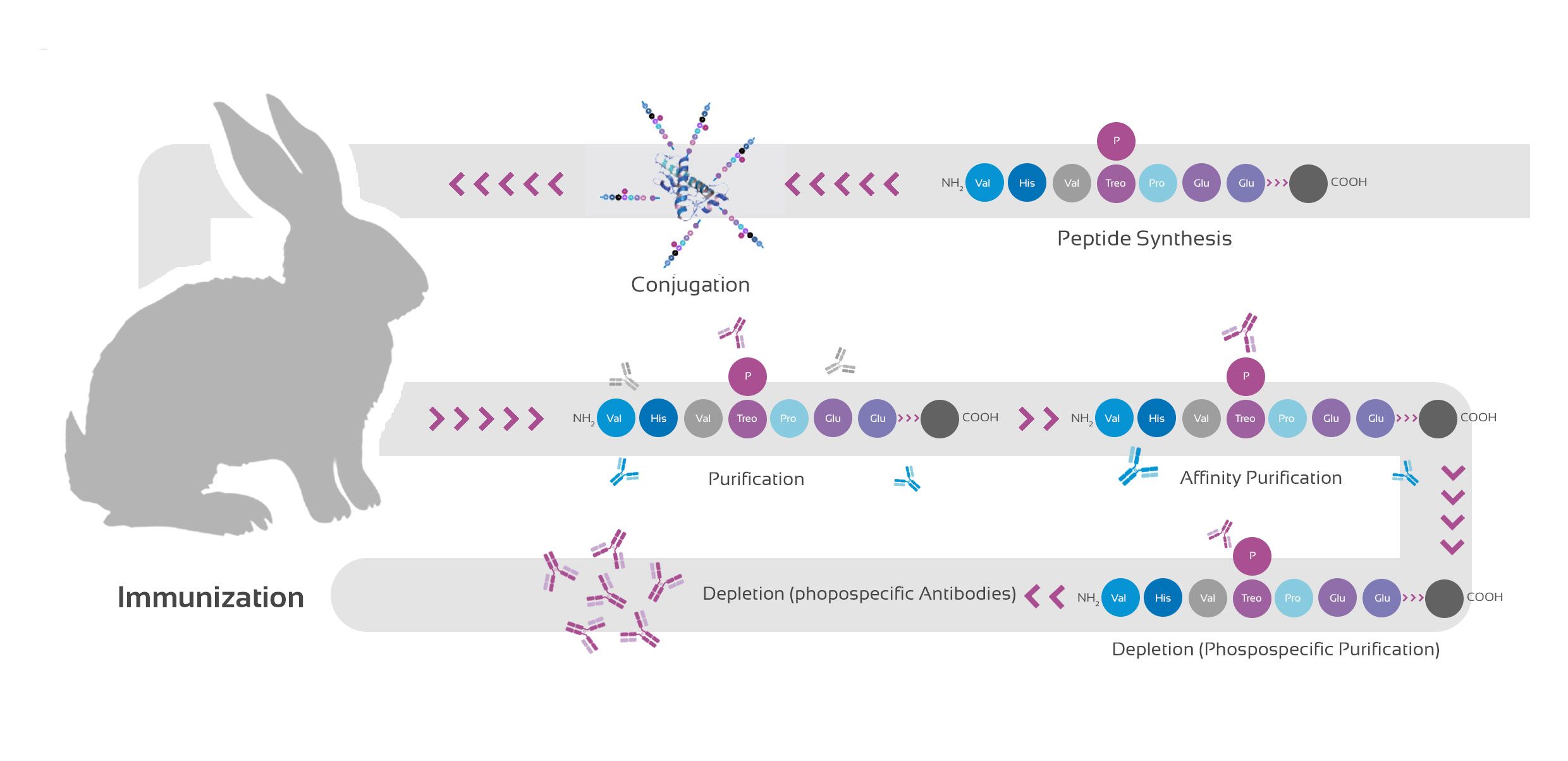

Monoclonal Antibodies

For the last 15 years, Immunostep has generated dozens of projects in which the development of mouse monoclonal antibodies has been the key to our clients reaching their goals. We can guarantee high affinity and high specificity antibodies that will help our customers to succeed in achieving the aims of their research. We will find the solution they require from a large variety of antigens, which can be developed internally, or from the clients’ previous developments.

Using proteins as antigens, we can obtain monoclonal antibodies against the conformational epitopes of the target protein. This will maximise the antibody’s chances of binding to the native protein in a greater range of applications. Thus, from the sequence of this target protein only, we can carry out the whole process internally, and control and design the complete chain of development together with the client.

Phase 1: Study and Immunization protocol

It is the key phase in the entire process. Here the client’s needs are established, and subsequently the whole process is designed so as to obtain both the ideal antigen for the development and the control points. The immunisation period will vary from 30 to 90 days as needed.

- Standard protocol or customized design.

- Number of animals: 5 Balb/c mice.

- Intermediate bleeding for immunisation control.

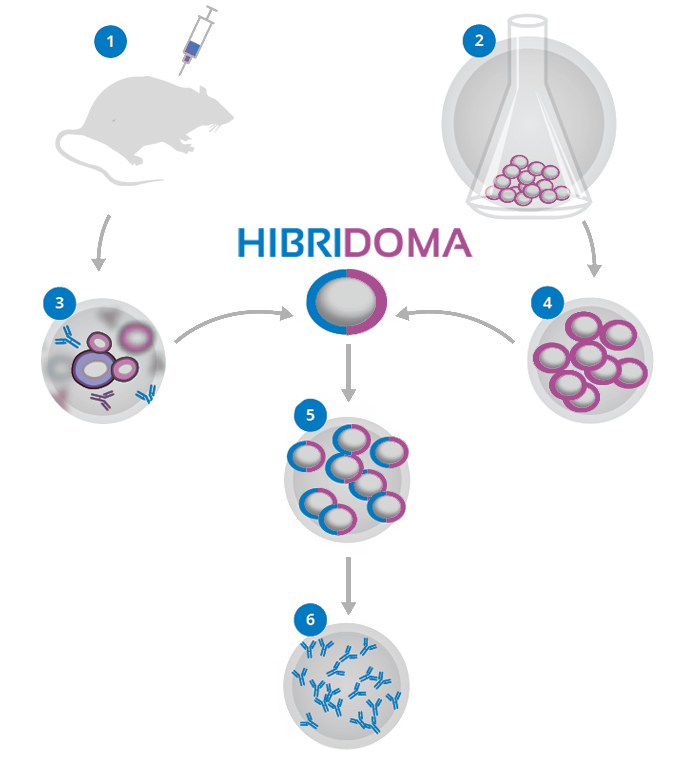

Phase 2: Cell fusion, Selection and First Screening

An SP2 murine cell line is used to obtain hundreds of clones through thebinding of the splenocytes of immunised animals. These clones will provide a starting point for work on the localisation of the antibody required by the client.

- Conventional ELISA and/or WB for screening

- Validation with the immunogen

- Capture ELISA

- Competitive ELISA

- FACS screening

- Other additional types of screening are available

PHASE 3: Cloning and Second Screening

Once these antibodies/clones have been localised, we will begin to work on them in order to adjust the antibody, now a researcher’s tool.

Delivery of supernatants to the customer and consensual selection of the candidate clones. Customers make their choice according to their own tests.

PHASE 4: Stabilisation and Cryopreservation. Characterisation of the selected clones.

Tests such as Ig Isotyping, Mycoplasma tests etc.